DUET

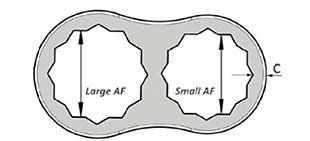

The DUET has two sizes in the one tool and leverages the power of the embedded magnets hold to carbon steel creating a hands free operation. The magnets will hold the tool upside down & underwater in a variety of conditions

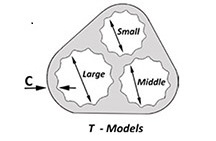

TRIO

The TRIO has three sizes in one tool and is perfect for small sizes from 19mm to 32mm. The TRIO also leverages the powerful magnets creating a hands free operation. The magnets will hold the tool upside down & underwater in a variety of conditions

SETS & CASES

Sets are created for your required sizes and are custom fitted for your convenience.

We also have a number of ruggedised cases to hold the tools in a clean and safe environment.

DUET METRIC AND IMPERIAL SIZING CHARTS

DUET SIZES | METRIC (SMALL A/F) | METRIC (LARGE A/F) | IMPERIAL (SMALL A/F) | IMPERIAL (LARGE A/F) | C (mm) | WEIGHT (KG) |

|---|---|---|---|---|---|---|

DD-27 | 27 | 32 | 1-1/16″ | 1-1/4″ | 8 | 0.3 |

DD-36 | 36 | 41 | 1-7/16″ | 1-5/8″ | 9 | 0.6 |

DD-46 | 46 | 50 | 1-13/16″ | 2″ | 10 | 1 |

DD-55 | 55 | 60 | – | – | 10 | 1.2 |

DD-2316 | – | – | 2-3/16″ | 2-3/8″ | 10 | 1.2 |

DD-65 | 65 | 70 | 2-9/16″ | 2-3/4″ | 12 | 2 |

DD-75 | 75 | 80 | 2-15/16″ | 3-1/8″ | 13 | 2.1 |

DD-85 | 85 | 90 | – | – | 13 | 2.8 |

DD-312 | – | – | 3-1/2″ | 3-7/8″ | 13 | 2.8 |

DD-95 | 95 | 100 | – | – | 13 | 3 |

DD-414 | – | – | 4-1/4″ | 4-5/8″ | 13 | 3.2 |

DD-105 | 105 | 110 | – | – | 13 | 3.6 |

DD-115 | 115 | 120 | – | – | 13 | 3.7 |

TRIO METRIC AND IMPERIAL SIZING CHARTS

TRIO SIZES | METRIC (SMALL A/F) | METRIC (MIDDLE A/F) | METRIC (LARGE A/F) | IMPERIAL (SMALL A/F) | IMPERIAL (MIDDLE A/F) | IMPERIAL (LARGE A/F) | C (mm) | WEIGHT (KG) |

|---|---|---|---|---|---|---|---|---|

T-19 | 19 | 22 | 27 | 3/4″ | 7/8″ | 1-1/16″ | 8 | 0.3 |

T-24 | 24 | 27 | 32 | 15/16″ | 1-1/16″ | 1-1/4″ | 8 | 0.4 |

if you require CUSTOM SIZING – drop us an email or call. We’re happy to help.

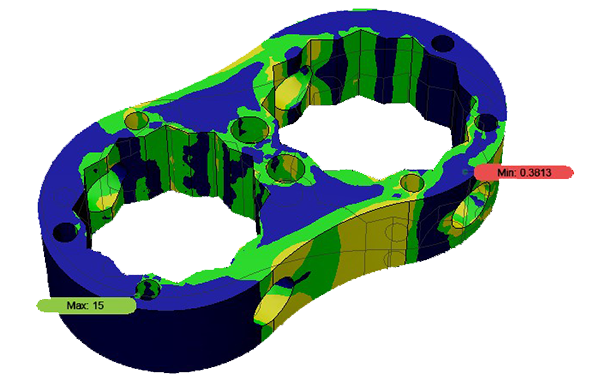

RIGOROUSLY TESTED

designed to withstand the harshest conditions

Our products have undergone rigorous Finite Element Analysis (FEA) testing. FEA is a computerised method for predicting how a product reacts to real-world forces, such as, vibration, heat, fluid flow, and other physical effects.

Finite element analysis shows whether a product will break, wear out, or work the way it was designed. It is called analysis, however in the product development process, it is used to predict what is going to happen when the product is used.

Rest assured our DUET products are tested over and above standard loads, to ensure you are getting a quality product!